Background

This system replaces commonly used big magnetic drills and drill bits. Instead, it utilizes a light-weight mag drill and annular cutters (“slugger bits’). With the C-Sert System, you’ll open up the C-Sert’s pilot hole by making several lap cuts with the annular cutters rather than making one cut with a heavy mag drill and a drill bit. This saves your back, it saves you time, and it keeps you safe.

How to open up the Pilot Hole

- Open the mag drill case. Read the manufacturer’s instructions. Yeah, yeah, we know no one reads the instructions, but read the ones that matter. Forget the stuff that says, “Don’t stick your fingers in the electrical outlet…” You know what we mean.

- The drill comes with a threaded stud that keeps the chuck from damage in shipping. Remove the stud by using a pliers and the tapered “shiv” that comes with the drill to knock the chuck loose. If the chuck comes completely loose, make sure the “tang” on the end of the Morse taper lines up with the internal slot in the chuck. Use a flashlight if you have to. Then give the chuck a good solid blow to make sure it’s seated fully, or else it can go bad.

- Put everything you’ll need on a cart next to your project. No running back and forth to the crib to get stuff you forgot! That includes everything we sent you, plus plant air to blow out chips, a hammer, ratchet or torque multiplier, sockets, and a screwdriver to break up the chips the C-Sert will make as it cuts its way in.

- Put the 60-degree center in the chuck. Tighten one set screw.

- Plug in the drill.

- Center the drill on the hole you’re going to open up. Turn on the drill’s magnet. You may not get the drill centered the first time you try. If you don’t, just turn off the magnet briefly and fine-tune the center. You’ll get it. From this point on, DON’T TURN OFF THE MAGNET UNTIL THE HOLE’S FINAL PASS IS DONE.

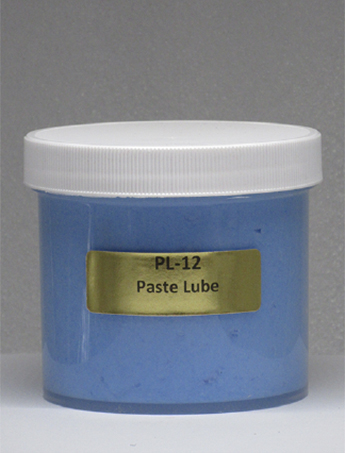

- Remove the 60-degree center. Pick up the first annular cutter (check the enclosed chart to make sure you have the right one!) and stuff some paste lube into it. A teaspoon is plenty. Put the annular cutter into the chuck and tighten both set screws down well. Turn on the drill. Here’s where you need some experience and common sense. YOU determine the feed rate. At first, you’re going to get some chatter. Don’t let it bother you. Press through it until the cutter starts to bite smoothly. Then let the cutter do the work, NOT YOU. There’s no problem in going too deep. To make things go faster, mark the flutes of the cutter with indelible metal marker, or mark a dowel or “chopstick” as a depth gauge and check as you go. Your hole just has to be deeper than the C-Sert’s length.

- Once you’ve reached the right depth, back out the cutter. DON’T TURN OFF THE DRILL’S MAGNET! Loosen the cutter. Replace it with the next, larger cutter. Remember first to put a teaspoon of paste lube in the cutter. Tighten the cutter well in the chuck. Drill to depth, same as before. You’re done.